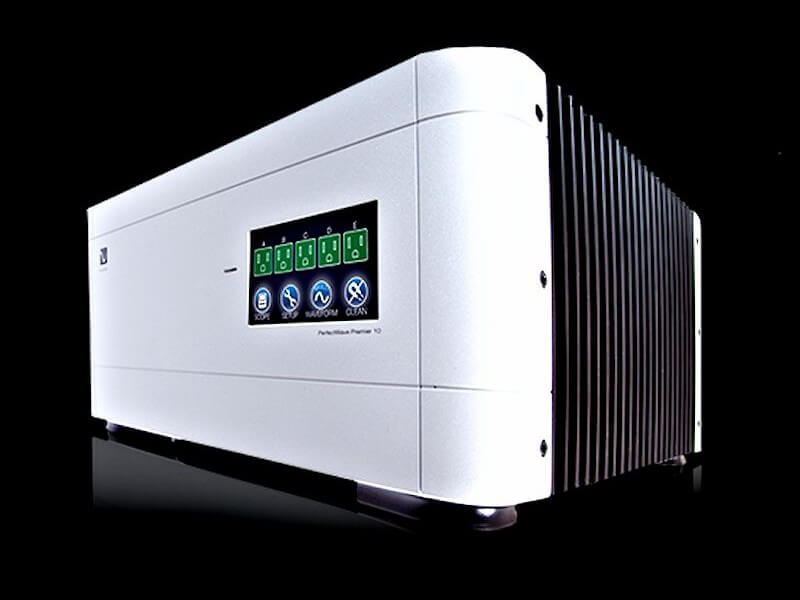

The PerfectWave P10 is the largest and most advanced high-end personal power generating station in the world. Capable of powering any size system with pure sine wave power, generated internally with a fully analog power amplifier, the P10 brings forth all that’s possible from your system and ensures you get the same great performance every time you listen.

The P10 is our biggest and best Power Plant yet. With 5 separate regenerated zones and 1500 watts of pure regenerated power, the P10 can handle any size system you want to power. From medium to large power amplifiers to the smallest pieces of source equipment, the P10 will work magic on your system’s performance. Only the very finest high-end system around the world use the P10 Power Plant and this is the piece to strive for.

With your system powered directly from the output of the P10, dynamics and openness are breathtaking. New voices, new harmonics and a renewed sense of musicality are yours the moment the P10 starts up. This is clearly one of the most important pieces of audio equipment you can own – building a firm and reliable foundation for your system that will serve you for years to come.

How it works:

The PerfectWave P10 Power Plant takes your incoming AC power and converts it to DC, similar to what comes out of a battery, and then with patented PS Audio technology regenerates and produces new sine-wave-perfect, regulated high current AC power. In the process of regeneration any problems on your power line such as low voltage, distorted waveforms, sagging power and noise are eliminated.

Since the introduction of Power Plant regenerator technology in 1997, many reviewers as well as many thousands of customers around the world have experienced for themselves just how critical and unique a Power Plant is; the term accessory doesn’t begin to describe its value. One of our customers, a long-time reviewer for one of the established audio journals, remarked that “Its the first component anyone serious about high-quality audio should get.â€

It’s good to understand the importance of power in a high-end audio system. Everything we see and hear through our system is really the power from our home’s wall socket manipulated to make music through our speakers by our electronics. The quality of that power is critical to the success of any high-end system.

Legacy power conditioners:

Traditional power conditioners have been widely available for several decades and range in price from a few dollars to multiple thousands of dollars.

Most power conditioners on the market today are passive filters. This means there are only passive parts inside such as capacitors, resistors, transformers and coils of wire. Power conditioners do not have the ability to add missing energy back onto the power line to correct for the serious issues in the AC.

While some of the better respected high-end power conditioners do provide a significantly better sound and performance level for many systems, they are unable to address the fundamental problems found on the AC line. Unfortunately, this means they cannot ensure your listening and viewing experience will always be the same. Quite simply put, by relying on passive means to help the AC power, one relinquishes the security and reliability of a system running from a PS personal generator.

The problems with power:

AC power that is available in our homes is not perfect and is getting worse with time. Problems include fluctuating levels, noise, distortion, harmonics, unreliable performance during certain hours of the day and dynamic losses.

All AV equipment relies on this AC power to produce the music and video we listen to and watch in our systems. The quality of that AC power has a direct effect on the audio and image quality in a high-end system and without steady, perfected power, one cannot depend on the same level of performance day in and day out.

Legacy technology passive power conditioners address none of the real problems with power in our homes.

Power Plants are not power conditioners:

Power Plants are personal AC generators that provide hard working, perfected results from the AC power line. Power regeneration uses active components, like those found in large and powerful audio amplifiers, to rebuild the AC power and produce clean, clear, distortion free, regulated AC to the equipment.

Power Plants also provide excellent protection and cleaning of radio, cell phone and computer interference, but more importantly, regeneration provides a steady, regulated, low impedance source of pure AC, unaffected by the equipment’s demands for power.

The key to the Power Plant’s success and what makes it so unique in the industry is the way it makes the power better.

Instead of simple filtering, as a legacy power conditioner does, the Power Plant actually repairs the main power issues actually caused by the equipment itself: dynamic fluctuations.

Dynamic fluctuations occur with nearly every power amplifier or receiver on the market today. When a loud musical passage is reproduced, the power amplifier draws more power from the wall to feed the loudspeakers. When this occurs, the voltage at the wall decreases in direct relationship with the loudness of the musical passage. Louder is worse.

Traditional power conditioners only worsen this already bad situation:

If, on the other hand, the system is powered from a Power Plant AC regenerator, the problem is eliminated 100%. Dynamic voltage fluctuations are stopped completely, the power amp receiving perfectly regulated, steady AC power regardless of the demands from the power amplifier.

In a high-end system, where perfection is hoped for and compromise is not an option that’s acceptable, the improvements brought by a Power Plant are instantly recognized with a simple audition that shows both with and without perfected power.

The touch panel:

Touch the full color display on the front of the Power Plant and a whole world of opportunities open up. From here you can change all your settings such as the turn on/off sequence, adjust the output voltage to the perfect level, turn individual zones on or off and measure the power quality with either the built in oscilloscope or the THD analyzer.

The P10’s front panel controls offer a wealth of options not normally associated with AC power products such as the ability to measure the distortion of the incoming and outgoing waveforms plus the ability to actually see the waveforms with the color oscilloscope.

MultiWave:

One of the major advantages of generating new power from old is the ability to also generate new waveforms that enhance the capabilities of the power feeding your equipment.

MultiWave extends the peak charging time of the sine wave so connected equipment has more energy storage and less power supply ripple. Turning MultiWave on is like adding a larger capacitor bank to your connected equipment’s power supply. The audible results are dramatic and produce a bigger soundstage that sounds far more natural than with a simple sine wave.

CleanWave:

CleanWave is another unique feature to the Power Plants and helps connected equipment demagnetize their transformers. AC power is never quitesymmetrical and the small asymmetry that occurs can magnetize connected power transformers.

Activating CleanWave from either the Power Plant remote control or front panel touch screen can remove this problem from connected transformers resulting in far cleaner audio.

100 times lower output impedance:

Low output impedance is critical to maintaining a dynamic and robust presentation. Dynamic sags in the power line occur whenever your power hungry equipment demand power to drive your loudspeakers or projector causing noticeable degradation in the performance. Placing anything in the path of the power, like a power conditioner, only worsens the problem.

A Power Plant, on the other hand, regulates the power and provides a constant output irregardless of the dynamic demands of power hungry equipment or your neighbors. When your power amp is asked to produce loud orchestral levels you want to make sure it has all the power it needs. Power Plants have such low output impedance that even the hungriest of amplifiers won’t be starved for clean AC power. The results of feeding your equipment with low output impedance are dramatic:unrestrained dynamics even under the loudest passages, an open wide soundstage that does not collapse with volume and a naturalness to the music that is remarkable.

Owners who have invested in a Power Plant can rest assured their connected equipment will be safe from any power line event such as over voltage, under voltage, surges, spikes and potentially threatening problems.

The input voltage to the Power Plant is fully protected by state-of-the-art clamping devices and the output of the Power Plant is fully regulated so even large voltage swings that would normally damage connected equipment are made safe by either clamping or regulating. In most cases, connected equipment enjoys the protection and performance benefits of fully regulated power, even under extreme circumstances.

High current soft start

Another protective measure found on some Power Plant models is a high power soft start feature.

The P10 has a separate high-current zone that soft starts even the biggest power amplifiers.

With a Power Plant there’s no longer any need to worry. Using the unique high current zone built into the Power Plant, even power amplifiers that might trip a home’s circuit breaker are soft started and power up as nice and polite as could be.

This soft start feature also helps prolong the life of connected equipment from large inrush currents needed to fill up empty power supply capacitors.

Monitor your system’s heartbeat:

You can monitor your power quality and performance of your equipment from the front panel of the P10 with both its real time distortion analyzer and working oscilloscope. Measure everything that’s going on affecting your system’s performance. You can also monitor and control your P10 over the internet from anywhere in the world.

The P10 will monitor your power line quality and report any problems to you through the web page, text alerts or emails sent anywhere you wish. It’s up to you. The P10’s real-time and on-line measurement system includes surges, voltage levels, power usage and power quality as measured by THD (Total Harmonic Distortion) on the line.

The data is stored on our servers and available via the web interface for the P10. Customers can look at power quality over time, or drill down to specific times of day to find out if there’s a problem involving the home’s power. Sagging voltages, high distortion and multiple brownouts are occurring more than one might think. With the installation of a P10 in the system, you can accurately record events and present them to the utility company for repair or just keep a log.

Connect from anywhere in the world:

With a P10 system installed, not only can you check system and power line status from anywhere in the world, get emails sent to you from the device (if you want) and be assured you’re always connected to the internet, but you will also be able to go a lot greener than ever before.

The P10 will allow you to schedule system ‘vacations’ or down time so you’re not burning power when you don’t need to. This can be in the middle of the night, or when you’re on vacation and when you’re ready, the P10 turns everything back on for you zone-by-zone. Perhaps there are a few critical components you want to remain on, but others are OK to shut down and save power. No problem.

To access this feature there is a simple graphical calendar. Simply click on the dates you want the system to turn off and the dates you want it to come back on and everything will be ready for you upon your return. You can schedule your equipment (some or all) to be warmed up and ready to. And if your equipment needs an IR command to actually get it out of standby, that’s no problem either. The P10can easily send IR commands on schedule as well.

Input naming and customization:

With 5 zones available on the P10 it is important to know which piece of equipment is being powered by which zone so you can access from either the front panel or the web interface. On a P10 it’s easy. You can name each zone anything you wish via the P10’s easy to use graphical interface available online or through the front panel touch screen.

Once the outlets are named then it’s quite easy to schedule when they turn on/off or the sequence that they are powered on. For example, you may wish for all your sources to turn on first, warm up and then when you decide it’s long enough, your power amps will turn on.

IR and trigger controls:

In the back of the P10 there are two mini jacks that can be assigned as either an IR input or output or a DC trigger transmitter or receiver. For the IR capabilities, the P10 can be assigned up to 15 separate IR commands for any zone and these IR broadcasts can be triggered by any number of assignable events. This helps P10 owners maintain complete control over not only the AC power, but by directly controlling that same equipment through a remote control.

If you have equipment that needs a DC trigger to turn it on or off remotely, you can assign one of the mini jacks to be either the sending or receiving unit for these commands and remotely turn on/off equipment or have that equipment remotely turn on/off the P10.