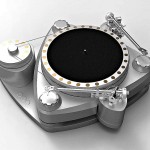

The Ascona story starts with the platter on which the record sits – because the perfect turntable requires a resonance free platter rotating perfectly, with great stability. A very high mass platter is the answer, but needs designing carefully to achieve the desired result, high mass on its own is not enough.

Then there is the motor to perfectly rotate the platter and the ‘arm board’ to perfectly hold the arm – all needed radical re-thinking to achieve the goal – the best sounding turntable Acoustic Signature have ever produced, the best turntable ever perhaps?

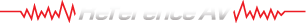

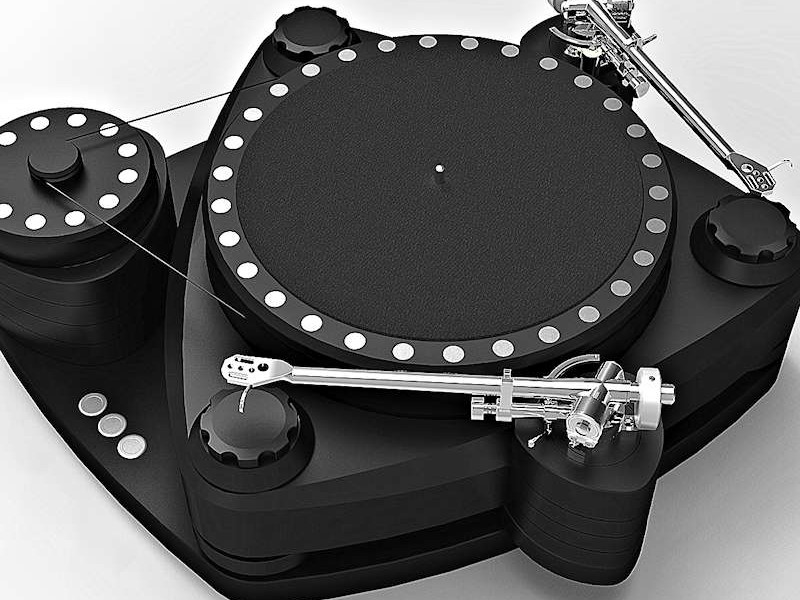

Here are the technical features that make the Ascona so good: The chassis is milled out from a 70mm thick block of aluminium and forms part of the integrated turntable ground-plate. Combined with the new platter the Ascona has a weight of 80kg. The surfaces are ground by hand, a lengthy but essential process to achieve visual perfection.

The Design:

More ways to amaze. The new ASCONA is a consequent developed new design. It’s all combined with the award-winning performance, elegance, convenience and comfort that have made the mass turntable Series so successful. Perfect surface quality combined with the latest technology and flexibility. The full turntable assembly sits on a 35mm thick Aluminum ground plate. Here the feet for the Chassis and the motor are mounted. The Ascona includes the most exclusive version of the Silencer platter.

The Ascona employs 30 small Silencer’s on the very outer diameter of the platter; with an increase to the platter diameter to nearly 350mm to achieve this. A further 24 larger Silencers are used within the body of the platter. The tone arm mounting plates are adjustable. The mounting of any desired tone arm is possible, with a maximum of 2 tone arm mounting plates on one turntable. Three adjustable feet for simple macro and micro adjustments to level the turntable.

The Drive System:

For the new ASCONA Acoustic Signature combine a massive Aluminum plinth of 65mm with a 50mm massive Aluminum platter with a 345mm diameter. This is a perfect fit for the Tidorfolon bearing holding the platter and the exchangeable arm boards.

A new fully digital motor Electronic Alpha DIG provides perfect speed stability and easy operation. The Ascona has the most rigid armboard mounting units Acoustic Signature have ever produced., plus the 3 motor flywheel motor system in included with the Ascona.

The Platter:

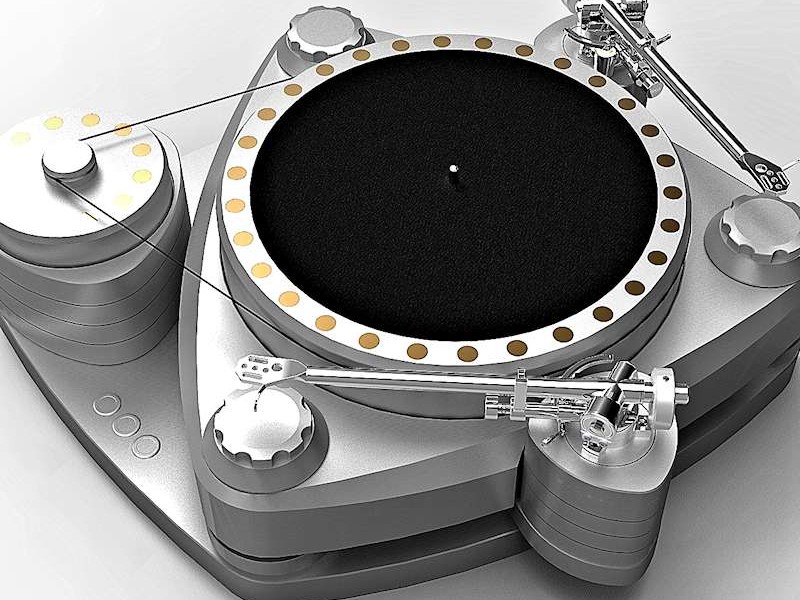

A 50mm solid turntable platter made of aluminum with 54 Silencer inserts. The platter is made of a very soft alloy to optimize its periodic resonance, and is coated on the rear side with resonance-reducing material. For the Silencer-Platter the development target was clearly defined: Elimination of vibration due to impacting airborne sound.

Elimination of bearing noise, increase of the gyrating mass. Serious elimination of all frequencies, especially in the range 400-6000Hz. This was achieved by drilling 54 holes into the platter. The manufacturing process for the precision of these holes was once more refined. The holes are drilled and afterwards separately “line-bored”. This allows a clearance of less than 1/100mm. Perfect conditions for the force-fitting of the 54 silencer modules. The “silencers” are now an integral part of the platter – but highly absorbing.

Existing vibration energy is quickly reduced and the Platter is immediately steadied. To avoid unbalances through the additional holes these are manufactured in the same setting as the outer contour. In this way the holes are absolutely true to the center of the turntable.

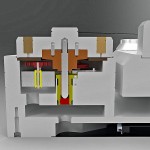

The Motor:

Acoustic Signature believe that a motor system for a turntable should have enough energy to speed up the platter but not influence him during rotation. They reach that aim by using a European made Synchronous motor with our own State of the Art motor control.

The external drive motor of the turntable is run by its own electronic controller, called the AlphaDIG. It is a brand new design where fully digital output stages and a quartz locked technology is used. It is impervious to the negative effects of mains voltage fluctuations and household appliances that produce ‘noisy’ mains that can have a very great detrimental effect on AC motors and therefore the turntable performance and ultimately the sound. A quartz precision DSP then produces a perfect sine wave at 24VAC to run the motor, resulting in a perfectly steady and constant platter rotation. The AlphaDIG control is the perfect design solution. This engine system is absolute stable in his rotation speed and in combination with the digital control easy to use and reliable.

The ASCONA comes with the 3 motor flywheel version motor drive. This combines a heavy Flywheel rotating at a high speed with a 3 motor drive. The results is a high inertia drive system which provides the most stable speed of any motor drives Acoustic Signature offer.

The Bearing:

The bearing is the heart of every turntable. Through fundamental research and development, Acoustic Signature have invented a bearing with the ideal performance characteristics of exact fit, extremely low noise, very low friction and long term stability. The platter bearing component is manufactured from special hardened and polished steel, with an extremely hard tungsten carbide ball at its base.

The bearing housing uses perfectly matched and ‘aged’ sinter bronze inserts which are self-lubricating; and therefore maintenance free. At the base of the bearing, is a specially developed ‘high-tech’ material TIDORFOLON. The bearing runs dry – without oil. Here we have ultra-tight tolerances and the Tidorfolon bearing is lifetime maintenance free. This Bearing is covered with a 10 year product warranty.